-

1986

The Road to Entrepreneurship

In 1986, Mr. Ruan Ruiyong, the founder of the company, abandoned the golden job in the state-owned company he had worked for many years. And then he registered the company which named “GRH” in Yancheng, northern Jiangsu. As soon as you enter the office, you can see a copper frame engraved with the corporate philosophy of “Customer as family”. In order to ensure that every employee can see it when they go to work. GRH had 300 national standard products on its inventory list within one year.

-

2002

The Large-scale Development

From 2002 to 2004, GRH truly embarked on large-scale production and ushered in an unprecedented grand occasion. The annual output of hydraulic distributors is as high as 1.3 million units-this number is undoubtedly a legend for the market at that time. Mr. Ruan, who had completed the original accumulation, had a firm belief that is to make GRH become a large-scale enterprise. So GRH started to renovate the plant and upgrade the equipments, and most importantly, to bring in talents.

-

2005

Industrial Transformation and Upgrading

Over the past decade, Mr.Ruan has invited well-known hydraulic experts to join the company. The product line of GRH has expanded from the initial national standard joints and distributors to hydraulic gear pump parts, gear pumps, gear motors and other hydraulic components. During this period, Mr. Ruan innovatively introduced an assembly line production system and combined with leading processing and production equipments. This innovation completely eliminates the customers’ troubles of waiting for goods and inventory due to the traditional order mode.

-

2006

The Product Diversification

The unique GRH model has experienced rapid development in the coorperation with customers.

GRH has achieved rapid development by ensuring the timely supply of each customer’s products, eliminating customers’ sluggish inventory and reducing customers’ inventory costs by more than 90%.

The total sales volume of GRH has been the best since 2003.In 2006, GRH built 4 spacious workshops that are opposite to the self-built factory area to manufacture different product series.

-

2007

Enter the International Market

In 2007, GRH established its first overseas marketing center to develop overseas business and promote hydraulic parts made in China to the world. At present, GRH has 1 manufacturing center, 2 overseas marketing centers in mainland China, strategic warehouses in North America, key customer service teams, authorized distribution agents, etc. There are more than 50,00 products with different varieties and specifications including American standard, DIN standard, BS standard and national standard. More than 1,000 customers in hundreds of industries around the world choose the products and services of GRH.

-

2011

The Road of Independent Research and Development

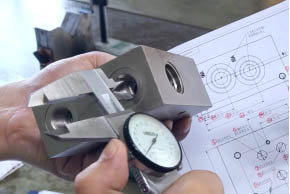

GRH has attracted many well-known domestic and international experts. Meanwhile GRH has successively established a number of new product divisions. Since the establishment of the electro-hydraulic proportional valve division, Mr. Ruan has insisted on hiring world-class talents, purchasing advanced processing equipment to design and manufacture best products in the international and domestic markets. GRH has obtained invention patents and several utility model patents.

-

2013

Diversification Stratagem

More and more customers hope that GRH can develop more high-quality hydraulic components. GRH is a trustworthy enterprise for customers. The market has also proved this point. Whether they’re ultra-high-speed gear motors, high-quality orbital motors, customized power units, or well-developed electro-hydraulic load-sensitive proportional valves, they have already enriched the product line of GRH. It also has attracted the attention of companies like Terex, Caterpillar, John Deere, YTO and XCMG.

-

2014

The Third-generation Modern Factory

The new plant with an investment of more than 100 million yuan was completed. With the relocation of the high-tech industrial zone, the production capacity was greatly increased. The annual output has reached 2.2 million units. A good working environment, 5S standard on-site management, humanistic care for employees, and subtle corporate culture have transformed GRH from a little-known private enterprise into a modern enterprise with continuous technological innovation and value-oriented.

-

2015

Won The Gold Medal

The market demand caters to GRH’s plan to develop high-end, high value-added hydraulic products, which is also GRH’s the first hydraulic motor product. In the same year, the “Load Sensitive Electro-hydraulic Proportional Multi-way Valve”, which has been developed for ten years, was recognized as a provincial engineering technology research center. GRH has been rated as a key cooperative supplier of “YTO” for three consecutive years. The “GKV80 Series Load Sensing Electro-hydraulic Proportional Valve” developed for YTO won the “China Agricultural Machinery Parts Products” Gold Award.

-

2017

A New Era of Intelligent Manufacturing

Manufacturing base has already introduced the German processing centers, British testing equipment, Japanese robots and other advanced equipment. Now, intelligent high-end equipments account for more than 60%. GRH has always adopted very strict quality control measures. GRH Manufacturing Center passed ISO9001 and implemented quality system certifications such as TS16949. Over the years, GRH has also become a qualified supplier for many companies with extremely stringent requirements such as aerospace, shipbuilding, railways, petrochemicals, etc.

-

2018

Development of Internationalization

With the increasing demands of overseas customers for inventory and on-site service, GRH has established warehouses in North America and Europe to provide on-site technical service support. The GRH brand began to appear on the cover of local mainstream professional media. In the same year, the second overseas marketing company operated independently. The multi-brand business strategy entered the implementation stage, GRH began to opening up a broader market.

-

2019

Core Competence Cultivation

With the introduction of highly automated equipment, GRH has entered the digital era of high-end intelligent manufacturing. Industrial robots have greatly increased productivity and improved the stability of component processing. The functions of the automatic test bench include electronic measurement and acquisition of test data, programmable automatic test, automatic analysis, printing reports and curves. Fully automatic cleaning and filtering system adopts multi-stage circulating filter to ensure high cleanliness and standard output. Besides, equipment also provides non-standard product design and customization services.

-

2020

A Keen Market Insight

Mr. Ruan is keenly aware of the market potential of cross-border e-commerce. It increased the pace of overseas deployment. It is believed that GRH will be able to call products without the MOQ limit, adjust the stock quantity according to the industry cycle at any time, provide after-sales quality service support of the distributor team for global customers in the near future.

-

2021

To Achieve Enterprise Centenary Inheritance

Mr. Ruan has an ultimate dream, which is to build GRH into a specialized enterprise with high-end technical strength and century-old heritage. Passing on GRH’s concepts of “customer as family”, “quality first” and “innovation leading the future”, He would co-exist and prosper with GRH.